News -

Losan Pharma drug delivery technologies

Losan Pharma, a privately owned, international operating CDMO meeting the hightest standard of global quality requirements, is providing solutions to enhance bioavailability, improve the stability of APIs and provide targeted, sustained release delivery of pharmaceutical products. We are glad to inform you that we have implemented several innovative technologies which could help you in the design of your formulations or drug products to overcome the above mentioned hurdles in development:

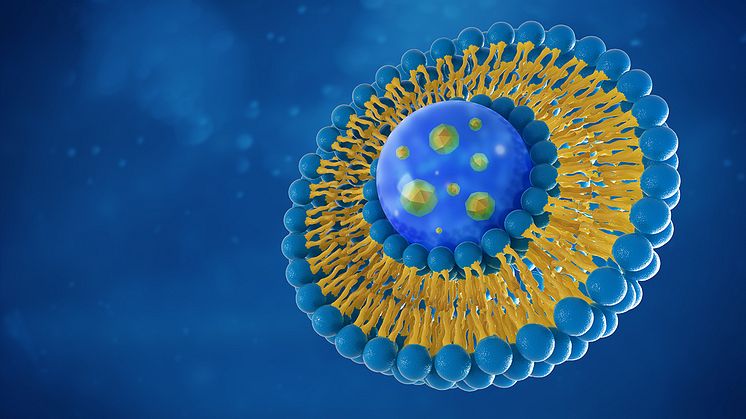

Nanotechnology

The major advantage of the Nanocrystal technology is the enhancement of the bioavailability (AUC, cmax, tmax) for BCS Class II-IV compounds by increasing the solubility and consequently the rate of dissolution of the corresponding drug. We are using a simple and streigthforward scale-up from screening (1-10 ml), pilot scale (0.5 – 10L) towards the commercial scale (50 - 600 L) even with high API loadings (up to 40%). Nanoliposomes with a Polydispersity Index of less than 0.3 with a high Encapsulation Efficacy of up to 60% can be produced using our proprietary NLS technology which could be an interesting approach for Peptides, Macromolecules and low soluble APIs.

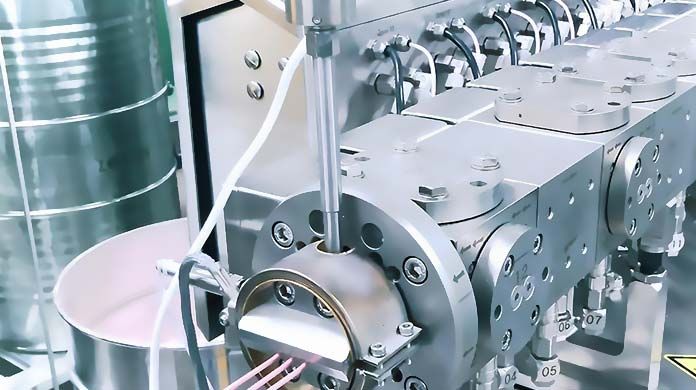

Hot Melt Extrusion

HME enables the amorphous encapsulation of active ingredients in water-soluble carriers. Losan has implemented sophisticated screening methods to determine potential polymer loading, solubility enhancement, permeability, and formulation stability. In a short period of time, formulations on a milligram scale allow a reliable formulation selection and scale-up trials can be started (kg range). Continuous manufacture on our production equipment including cooling by drum cooler or granule strand size reduction (hammer mill, granulator) to particles with targeted distribution can be offered.

Mesoporous Silica

Losan offers this new technology for low soluble compounds where a solubilisation and bioavailability increase is needed without impacting mechanical stress at elevated temperatures during the amorphisation and embedding into a polymer matrix. Different loading methods (solvent and dry loadings) are available.

3D printing of tablets

Losan has developed this new technology based on the Fused Deposition Modelling (FDM) technology. A cGMP conform 3D printer with dedicated printer head, high quality documentation and laminar flow to protect from foreign particles during printing is available. Printing on demand, a highly flexible approach for the dosage strength, for the design of tablets, and the delivery for personalised medication can be offered with this innovative technology.

Target release

The aim of our coating technology ranges from simply masking the taste or odour of drugs to the sophisticated controlling of site and rate of drug release. At Losan film coating (solvent, water-based) is possible using either fluid bed systems or drum coater technology. Fluid bed coating of functional, release-controlling polymers or protective coatings onto drug-layered cores, pellets, granules, or crystals. These multiparticulate systems provides advanced control of drug delivery and optimizes release profiles for drugs and drug combinations, especially if combined with our Stick pack technology for high dose strenghts and convenient applications.

Mini tablets

A fast development of mini tablet prototype formulations based on the product target profile and the available physicochemical data of the API can be offered. Uniform release profiles of the corresponding API in the GIT compared to monolithic dosage forms such as tablets are the result. Combination products with different APIs in each mini tablet formulation are possible.